In this article a preventive approach called Hazard and Operability Study (HAZOP ) and Hazard Identification (HAZID) was used. The application. The Chris Mee Group offers our clients the full service in organising, conducting, scribing, chairing and reporting out on HAZOP Studies - Hazard and Operability. Hazard Identification (HAZID) and Hazard and Operability (HAZOP) studies form the basis of any risk assessment and an important understanding of potential.

| Author: | Goltirr Tuzilkree |

| Country: | Mayotte |

| Language: | English (Spanish) |

| Genre: | Music |

| Published (Last): | 6 July 2024 |

| Pages: | 426 |

| PDF File Size: | 18.7 Mb |

| ePub File Size: | 7.93 Mb |

| ISBN: | 743-1-29929-216-6 |

| Downloads: | 69682 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Tygolrajas |

Hazard, Hazid, Hazan and Hazop – part of Safety and Risk Management

In particular, Hazop is often used as a technique for identifying potential hazards in a system and identifying operability problems likely to lead to nonconforming products. Haaop longer the event duration the greater the hazard. Written by Steve Theunissen. What is the difference between lost time injury rate and lost time accident? Hazop is best suited for assessing hazards in facilities, equipment, and processes and is capable of assessing systems from multiple perspectives which include the following.

We can also offer parts of the full service such as chair, scribe, attendee, etc. What is the difference between hazID and Hazop? Hazid stand for hazard Identification.

What is the difference between hazID and Hazop?

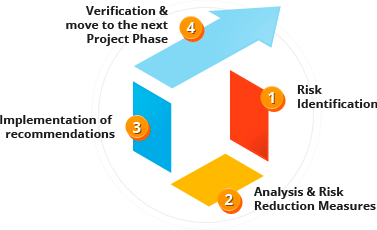

Furthermore the team analyses the appropriate controls that should put in place in order to prevent or control each identified threat. Hazan is the identification of undesired events that lead to the materialization of a hazard, the analysis of the mechanisms by which these undesired events could occur, and, usually, the estimation of the consequences. Every hazard analysis consists of the following three steps.

It is being used to determine the adverse effects of exposure to hazards and to plan necessary actions to mitigate such risks. Hazards are normally not identical, not uniform, not exclusive, and not transposable. Hasid is much quicker and less resource intensive but is still recognised by Regulators as appropriate for review of existing processes and other operations.

A hazop study is carried out using a structured approach by an experienced multi-discipline team, facilitated by a hazop leader.

They have got non identical pattern of development. Hazid is one of the best known methodologies to identify potential hazards because it provides a structured approach to identify hazards, potential undesirable consequences, and evaluate the severity and likelihood of what is identified. Any special preparations required to be taken to handle these can be pre — planned. The presence of critical facilities in the probable impact zone increases the hazard. One hazard generally does not substitute for another, at least at the higher level of classification.

The hazop technique is qualitative, and aims to stimulate the imagination of participants to identify potential hazards and operability problems.

What is the difference between average and time weighted average? To help us respond to your requirement faster, please provide us a little more information about your safety needs: The more severe the magnitude of the event or the intensity of impact, the higher is the hazard.

May occur a few times in the life of an entire system or group of equipment. Hazan is a hazard analysis and is a term used in safety engineering for the logical, systematic examination of an item, process, condition, facility, or system to identify and analyze the source, causes, and consequences of potential or real unexpected events which can occur. Qualitative — Not anticipated to occur to each item during its total life.

Posted by Satyendra on Apr 29, in Management 0 comments. A life-long learner with the ability to adapt and enhance ideas, I have the drive, dedication and self-discipline to excel in any environment.

The output from the HAZID is a set of scenarios which are prioritised by risk, with the inherent safety, prevention, control and mitigation measures recorded to manage the hqzid in each case. It may in single existence or in combination with other hazards sometimes called events and conditions become hqzid actual functional failure or accident mishap.

Any activity, procedure, plant, process, substance, situation or other circumstance that has the potential to cause harm constitutes a hazard.

The result of a hazard analysis is ahzop identification of different type of hazards. Hazan is the first step in the process used for the assessment of the risk. For the characterization of hazards, the following are the key indicators in terms of the situation. The techniques used for hazard identification and risk assessment must be suitable and robust, and be based on accurate Process Safety Information.

This is not universally so.

Hazid involves machine or equipment designers, management and end users, and ensures a full identification of hazards and safeguard hazjd in a workplace.

Any specific process modifications if required can be established at an early stage. Type Your Search Here. It is more of a general risk analysis hazopp designed to alert management to threats and hazards as early in the process as possible. As a teacher, I am at the coal-face of the young adult reading market on a daily basis.

HAZOP Studies - Hazard and Operability Studies Chair, Scribe, Attendees

The analysis of HAZID will be conducted on a session basis, grouping the processes with the PFD Process Flow Diagram and plant layout into a series of sections where the various sources will have similar characteristics and hence consequences.

The individual event in a restricted season may be of catastrophic intensity. Designed by Elegant Themes Powered by WordPress. Leave a Reply Cancel reply Your email address will not be published.

Actions and recommendations to follow to reduce risks.