It appears you are located in United States of America. Stay on SAP Training Shop United States of America or choose another country or region. To learn more. You can use the Integrated Product and Process Engineering (iPPE) component to collect all the data for an entire product life cycle in one integrated model. Use. The Integrated Product and Process Engineering component (iPPE) lets you collect, in an integrated model, all product lifecycle data specifically for.

| Author: | Diktilar Tygodal |

| Country: | Samoa |

| Language: | English (Spanish) |

| Genre: | Science |

| Published (Last): | 26 July 2024 |

| Pages: | 263 |

| PDF File Size: | 4.67 Mb |

| ePub File Size: | 3.17 Mb |

| ISBN: | 187-1-72550-782-8 |

| Downloads: | 35629 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Batilar |

Hi, Are there any other examples for the zap of process structure, line design. Integration with the APO. This module is basically used in design phase of the Product.

Search or use up and down arrow keys to select an item. Line balancing is based on the duration that you define for the activities in a process structure.

Product Structure Using iPPE in PLM

Once the product is designed we can handover this product for manufacturing. For more information about the above components, see Variant ConfigurationClassificationand Change Management.

The process structure is the basis for line balancing in line design. For example a car has different aap like Engine, Chassis, Wheel, etc. Now the Car Company got an order for an economy car. We have the entire Product design with all the available variants. It is not necessary to assign precise materials or activities, for example, at this stage.

Product Structure Using iPPE in PLM | SAP Blogs

You can use iPPE for non-configurable and configurable materials. You can use a change number when you change a mode. I am trying to retrieve node names, materials, quantity etc.

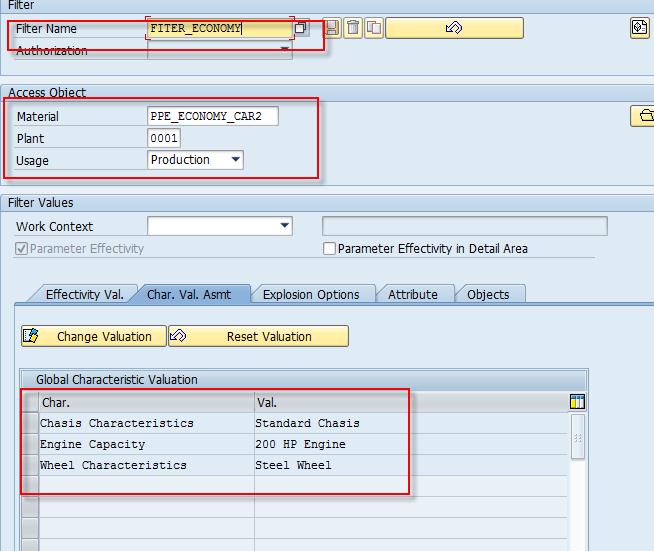

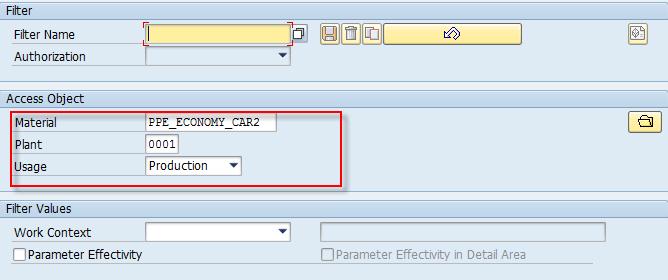

April 27, at 6: When you use ECM, the system can make operational use of different change statuses. To be able to use Integrated Product and Process Engineering, you also need the following components: Is the configuration profile same for Production and Engineering? When we store or create a filter. Creating Multi-Level Process Structures. Summary The above document just describes how a multivariant product can be designed in iPPE workbench.

Individual activities cannot be used more than once, that is, you cannot use the same individual activity in different routing headers or grouping activities. When you do not use ECM, there is exactly one valid status for each object in the system. CA Document Management System.

SAP Help Portal

In this case, you can only manage product data but no process data. You maintain the data in a functional structure, which you fill with more data at later stages in the product development, thus representing the whole product life cycle.

Now we need to ilpe the Classification View also to enter the Class name for the Material. Manage changes to routing data Engineering Change Management You can use a change number when you change a mode. We will design a Car which essentially comes in two variants Economy and Luxury. Also we need to mention the configurable materials for these access variants.

It is particularly suited to repetitive manufacturing. Calculate costs for production activities.

Assign documents CA Document Management System You can assign documents, such as technical drawings, texts, and so on, in a process structure, if the documents are edited in the Document Management System. You can assign documents, such as technical drawings, texts, and so on, in a process structure, if the documents are edited in the Document Management System. The components that you want to assign to the activities in the process structure must be maintained in the product variant structure.

Now we need to ipp a configuration Profile to this Configurable material.