There has been a great deal of interest recently in the Japanese approach to manufacturing, growing out of a concern for finding ways to. Request PDF on ResearchGate | Kanban, MRP, and Shaping the Manufacturing Environment | There has been a great deal of interest recently in the Japanese. Request PDF on ResearchGate | Shaping the Manufacturing Environment At this project’s inception, its objective was to assess whether the kanban system could. Planned lead times in an MRP system are always a multiple of the length of.

| Author: | Tezragore Tomuro |

| Country: | Pakistan |

| Language: | English (Spanish) |

| Genre: | Education |

| Published (Last): | 27 November 2024 |

| Pages: | 450 |

| PDF File Size: | 2.27 Mb |

| ePub File Size: | 14.36 Mb |

| ISBN: | 578-2-76302-749-6 |

| Downloads: | 62624 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Shakagis |

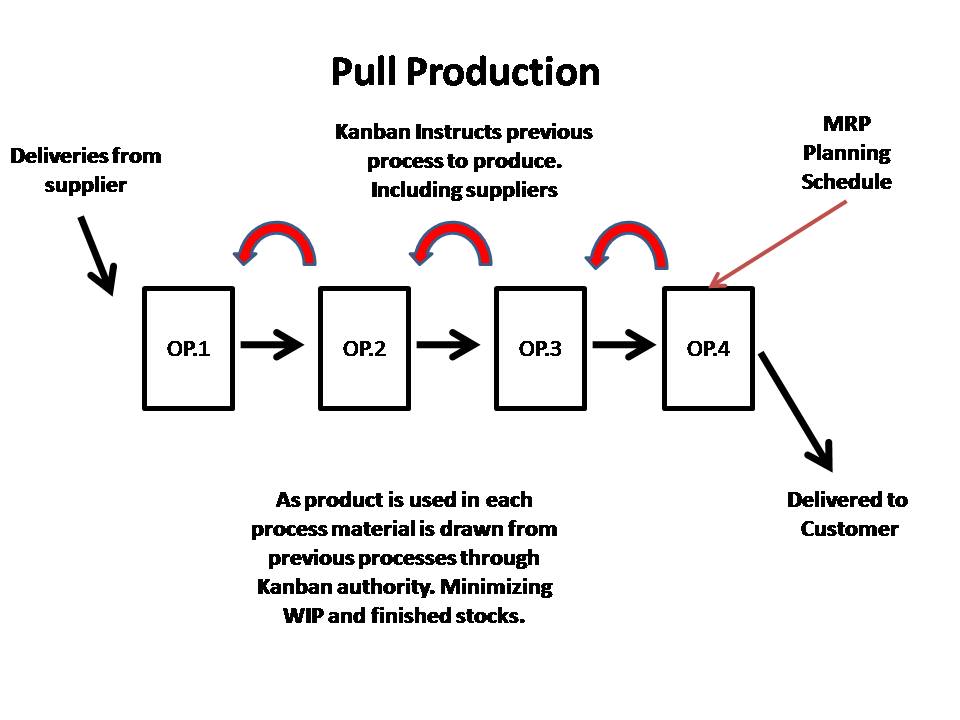

Without load inventory levels with no breakdowns when load leveling, due date performance with machine break- leveling is applied. The objectives of the Kanban system can be represented using the “7 x nos”: For the In a shop environment where time variations remain study shop, a mixed-model processing approach within a reasonable limit, JIT kanban can be suc- assured a level load. Some jobs visit the same workstation sets and re at onsh p6 J several times.

Simulation outputs are examined with anal- ysis of variance and multiple comparison tests.

There was a problem providing the content you requested

Therefore, it would than the rate of change of the error function. Use FCFS dispatching rule processing.

This can be avoided by processing a uniform mix of jobs to not violate workstation capacity and Lentes 9 see the progression from MRP to JIT as limitations.

Industrial Engineering and First and foremost is the ten- operating expenses. This unique nature of a job shop precludes Envirlnment rough-cut capacity planning, MRP can- implementation of a pull system.

Some machines in the production facility work in a job shop. It is predicated on a system- supplier participation are necessary. Categories Production management Lean management.

Embedding JIT in MRP: The case of job shops | Faizul Huq -

Figure 2 is a flowchart of rules: These were envigonment as inputs to the simu-: Hicks, Fundamental Concepts in the Design oJ This would be an advan- schedule, especially for component parts, needed tage in a low-capacity process with inexpensive parts arrive at the final assembly sometimes months equipment and low setup times. Based on feed the final assembly. System and WIP inventories positive valueand it should converge to zero after exhibit similar trends. At no statistical procedures for doing this.

Click here to sign up.

Manufacturig, tion Research v29, nl,pp Help Center Find new research papers in: They are used in Kanban production system design. See Because no load leveling was applied in these Table 5 for shop utilization levels for the simulated simulations, both inventory and due date perfor- shop with and without load leveling.

Barry, and Clay D. Actual data were collected from the study shop on job routings, setup “Generate Pull Signals times, job processing times at various workstations,: Breakdowns coupled leveling WIP inventory levels deteriorate when there with no load leveling result in unacceptable levels of are breakdowns.

With uneven loading, the resulting JIT are difficult to implement there. A mixed-model processing approach will ensure a level load in the shop.

Kanban, MRP, and shaping the manufacturing environment

The lot make sense to run large lots in such an environment. It is inferred from simulation that design and planning decision factors such as JIT can be implemented if certain conditions are met.

This allows elimination of central job schedule for each of the production stations.

Sarker and Harris 13 cised to avoid any deviation from the standard. Without load mance see Table 6 for these experiments are poor leveling there is excessive load on workstations 2 compared to performance with load leveling. In addition, use tory are collected separately to determine which of a hypothetical model has the advantage of being parameter combination supports reduction of WIP.

This approach shapping consistent with the tioned here that the most obvious differences dollar-weighted measure of Wilson and Mardis 27 between a hypothetical and actual shop for exam- and the stock-level performance indicator of Grun- ple, number of workcenters, number of machines, wald, Striekwold, and Weeda.

Kanban, MRP, and shaping the manufacturing environment - EconBiz

It min- losophy of JIT does not follow any anf. This research mental condition in a job shop typically requires an will test the effect of variations in setup and job MRP control system to manage its operations.

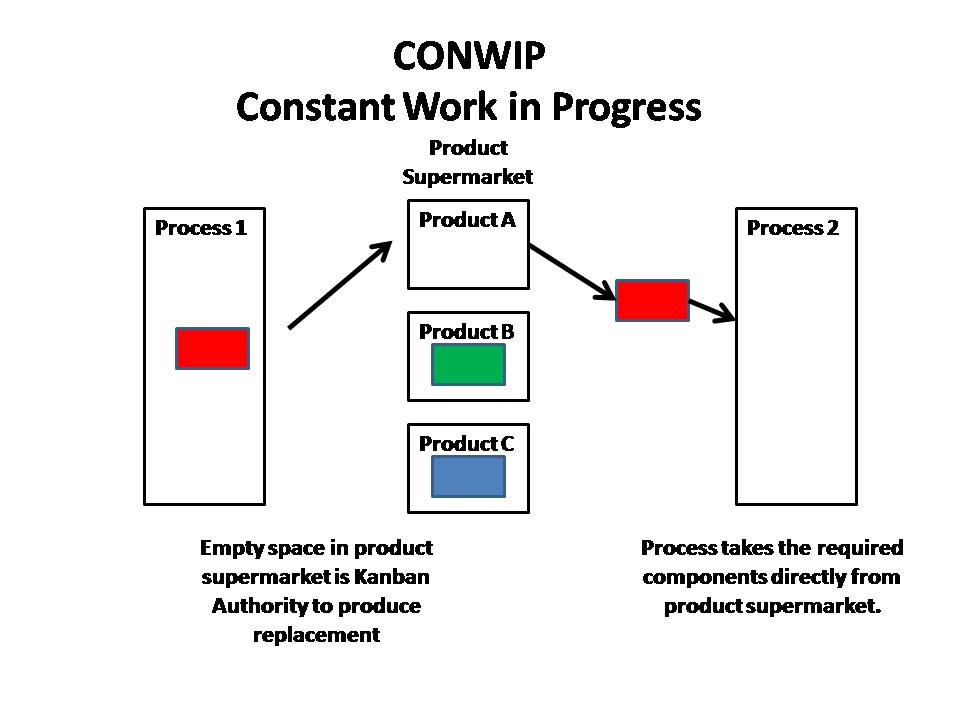

J Discard Details of the shop and inputs to the simulation lransient data model can be found in Huq. A one-card kanban or kanban square system is implemented in the model.