ASTM D B1 is a testing specification that measures the indentation force deflection of urethane foam and foam-like substances. ASTM D C specifies a method for measuring the compression force necessary to produce a 50% deflection over the entire top surface of the foam test . ASTM D Standard Test Methods for Flexible Cellular Materials-Slab, Bonded, and Molded Urethane Foams.

| Author: | Tojarisar Faugor |

| Country: | Kazakhstan |

| Language: | English (Spanish) |

| Genre: | Video |

| Published (Last): | 9 October 2024 |

| Pages: | 385 |

| PDF File Size: | 9.48 Mb |

| ePub File Size: | 5.23 Mb |

| ISBN: | 155-1-83255-479-8 |

| Downloads: | 59358 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Mazurn |

This is a very common situation in the foam industry.

For Test F, specimens aetm generally about mm long blocks with the width and depth the same as the material pad thickness. The initial height of the specimen is determined directly by the testing machine at the beginning of the first preload cycle. Variations of this method are described in the various factory regulations.

One specimen is necessary for this test. Call one of our engineers to learn more about which package is best for you. X Our website asfm cookies to ensure that we give you the best user experience. To increase the accuracy of the travel measurement, this standard specifies the correction for machine deformation. According to ASTM Dthe height and travel-zero point is redetermined before the measuring cycle. Samples come in a variety of forms including slab, bonded, and molded flexible cellular urethane foams.

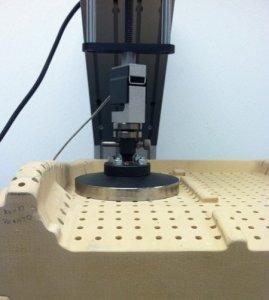

The Universal Test Machine would be used for higher forces or very large specimens. Force range of 5 kN to kN 1, lbf tolbf Adjustable test space The most popular choice for static tension and d374 tests F3574 dual column testers are available in both tabletop and floor standing models.

Compressive Properties/Compression Stress Value/Compression Stress-Strain Characteristics

The and are lower force options best for foam testing, the having more test space for larger specimens. The specimen should be mm X mm X 50mm. By continuing to browse our website, you are agreeing to the use of cookies.

This test will measure the IFD properties of the foam specimen before and after fatigue cycling. Forces up to 10 kN 2, lbf Low force tabletop systems Modular series of five frame options with adjustable test space Affordable testing option for tension, compression, bend, peel and much more. We recommend you purchase and read the full ASTM standard to achieve the best results.

ASTM D Testing Equipment for Flexible Cellular Urethane Foams

One specimen should be tested. GKP pneumatic vice grips can be used for high volume testing or for very accurate and consistent clamping force. Generally the test consists of three preload cycles, followed by a measuring cycle in which the characteristic values are determined. These versatile test machines can be configured to test in both tensile and compression.

Dog bone specimens are cut from a Hysteresis tests measure the difference in area under the curves during loading and unloading, representing energy loss. You are seeking to quantify the firmness of your foam.

Method I3 is similar to ISO The specimen for Atm B1 consists of the entire product or a suitable portion of it and should be no less than mm W X mm L X mm thick. The methods used by Renault and PSA are exceptions. Asttm engineers are very familiar with foam testing to ASTM D and can help guide you through the process with the correct compression test machine.

This testing machine is equally ideal for research and development and for routine quality assurance testing. Our website uses cookies to ensure that we give you the best user experience.

ASTM D specifies an additional specimen with a round cross-section and a diameter of 57 mm. Recovery time tests determine the recovery time of slow recovery memory foams. There are several test procedures in this standard to help determine the compression, deflection, tear and tensile characteristics of flexible cellular materials urethane foams and polyurethane foams.

Cuts test specimens from stock material Available for a wide variety of ISO and ASTM standards Consistent specimens for consistent results Manufactured with tool steel to resist damage and wear over time. For this reason it is not possible to effectively compare measured values that are determined from specimens of various dimensions using this test method.

This test is similar to ISO This tensile test determines the effects of a tensile force applied to foam. IFD Indentation force deflection and ILD indentation load deflection are two of the more common compression tests in this standard.

A 40 mm cut is placed down the middle of one end and 3 samples are required. ASTM D is a widely accepted test standard for testing soft polyurethane foam.

Indentation Aetm Gauge Asttm test for urethane foams used to determine how thick the padding is after being loaded by an average weight person. If possible a completed manufactured product should be used as your testing specimen. AllroundLine for individual testing requirements and all applications The optimum solution for demanding testing applications, whether in quality control or for research projects.

Compression hardness ISO , ASTM D

The test consists of a total of five test cycles, of which the first and the last are evaluated. GK mechanical vice grips can also be used. Standards for This Test The standard specimens have a quadratic cross-section with a lateral edge length of 5 or mm.

The compression stress value is the pressure resistance that a defined specimen under specified environmental conditions applies to a defined whole-surface compression. In this scenario, the deformation behavior of the specimen is relatively complex.